As global manufacturing accelerates towards high-end and intelligent production, non-ferrous metals—key industrial materials—face increasingly stringent requirements for core parameters such as crystallization temperature, electrical conductivity, and thermal conductivity. In the fields of new energy storage and advanced metallurgy, precision in molten salt conductivity measurements must be controlled within ±0.5%, while crystallization temperature deviations should be kept below 2°C. These stringent standards push the boundaries

of material performance and impose unprecedented accuracy demands on high-temperature molten material property testing equipment.

Aluminum Electrolysis Process: Enhanced crystallization temperature accuracy reduces energy consumption per ton of aluminum by 3% ("Light Metals," 2024 Research Report).

Molten Salt Thermal Storage for CSP: U.S.-based SolarReserve mandates molten salt (60% NaNO₃ + 40% KNO₃) conductivity measurement repeatability error below 0.3% (IEEE 1175-2023 Standard).

However, traditional metallurgical production remains largely experience-driven, with existing testing methods struggling to accurately characterize the critical physical properties of molten salts and melts. This limitation hampers process optimization and product quality improvement. Addressing this industry challenge, CHJT has developed a series of high-precision molten material property analyzers, capable of accurately measuring electrical conductivity, crystallization temperature, surface tension, viscosity, and other key parameters. These innovations provide crucial data support for the intelligent transformation of the non-ferrous metal industry, facilitating breakthroughs in technology and advancing high-quality development.

The advancement of high-performance materials depends on accurate property measurement. CHJT offers a suite of cutting-edge testing instruments to help enterprises enhance quality control and process optimization:

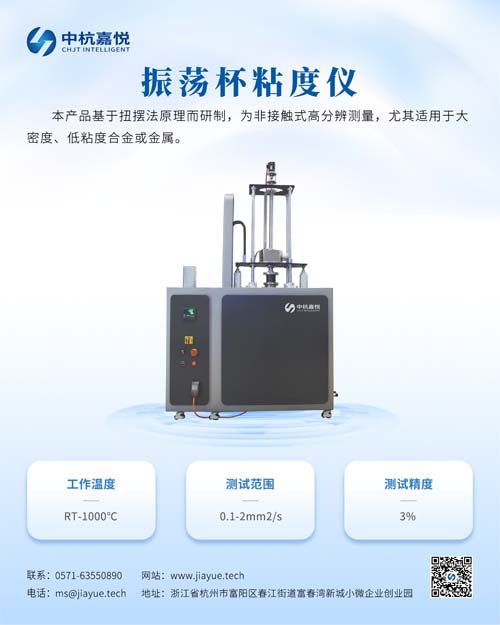

1.Oscillating Cup Viscometer: Co-developed with Shandong University, this instrument employs a torsional oscillation method to measure the viscosity of high-temperature liquid metals. It overcomes challenges posed by traditional measurement methods, which often suffer from material fusion issues at extreme temperatures. It operates at temperatures up to 1200°C, with a 2000°C version under development, and supports vacuum testing.

2.Comprehensive Molten Property Analyzer: Designed for high-temperature molten material analysis, this multi-functional modular system enables one-stop physical property testing, including electrical conductivity, crystallization temperature, surface tension, and density. Its flexible configuration adapts to diverse experimental needs, improving testing efficiency and reducing research costs.

3.Molten Salt Property Analyzer: Specifically engineered for molten salt systems, this instrument delivers precise measurements of electrical conductivity, crystallization temperature, surface tension, and density. It provides reliable testing solutions for industries such as new energy storage, molten salt electrolysis, and metallurgy, optimizing process flows and enhancing R&D efficiency.

4.Molten Salt Rotational Viscometer: Independently developed based on over a decade of experimental research, this device is primarily used in molten salt thermal storage systems. It measures density, viscosity, specific heat capacity, and thermal conductivity. The instrument features high-precision temperature control technology, ensuring stable test results and offering crucial support for new energy material development.

Smart manufacturing is key to improving production efficiency and ensuring material consistency. CHJT has introduced advanced metallurgical processing equipment tailored to intelligent manufacturing needs:

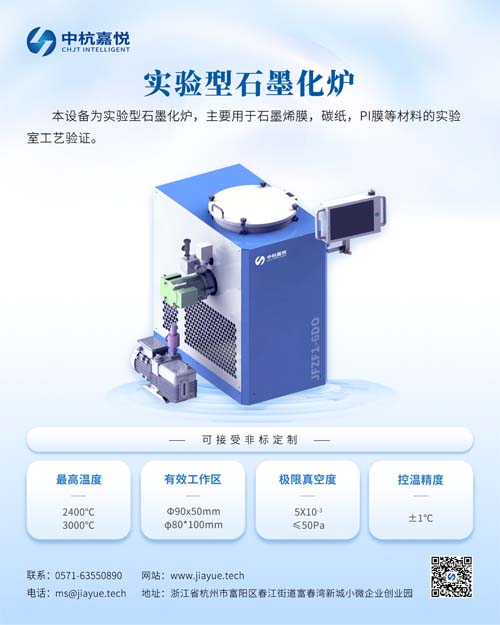

1.Laboratory Graphitization Furnace: Designed for laboratory validation of graphene films, carbon paper, and PI films. Its compact footprint, air-layer insulation, and highly efficient thermal retention structure significantly reduce energy consumption while maintaining optimal performance.

2.High-Precision Annealing Furnace: This equipment utilizes Kanthal resistance wires as heating elements and features an intelligent temperature control system with silicon-controlled rectifier (SCR) regulation, ensuring high-precision thermal processing. The furnace chamber, made of advanced foam ceramics, is housed in a dual-layer structure with an integrated air-cooling system to maintain low external temperatures.

By combining precision testing and intelligent manufacturing, CHJT is driving the non-ferrous metal industry toward greater technological heights.